Big ideas need a place to grow

Woolpower Forward is our platform for progress, a space where we challenge conventions and experiment to create the textiles of tomorrow. We believe that big changes start small, but always with the ambition to scale for real impact. It’s all about garments that use resources with care.

Through Woolpower Forward, we explore new materials and new production techniques. We test ideas on a pilot level, ensuring their feasibility before integrating them into our existing products. While we occasionally launch new products to explore and evaluate materials, our focus remains on scaling what works. Our long-term goal is to use our new knowledge to evolve the garments our customers already love, making them even more durable and responsibly made. We collaborate with industry experts to push boundaries and drive progress.

But innovation means nothing without transparency. That’s why we want to share both our successes and challenges, creating an open dialogue and holding ourselves accountable for our role in the textile industry. Let’s take our next step Forward.

Our first step Forward

Let us introduce an entirely new material. Which, in fact, is old.

Recycled yarn from our own production waste

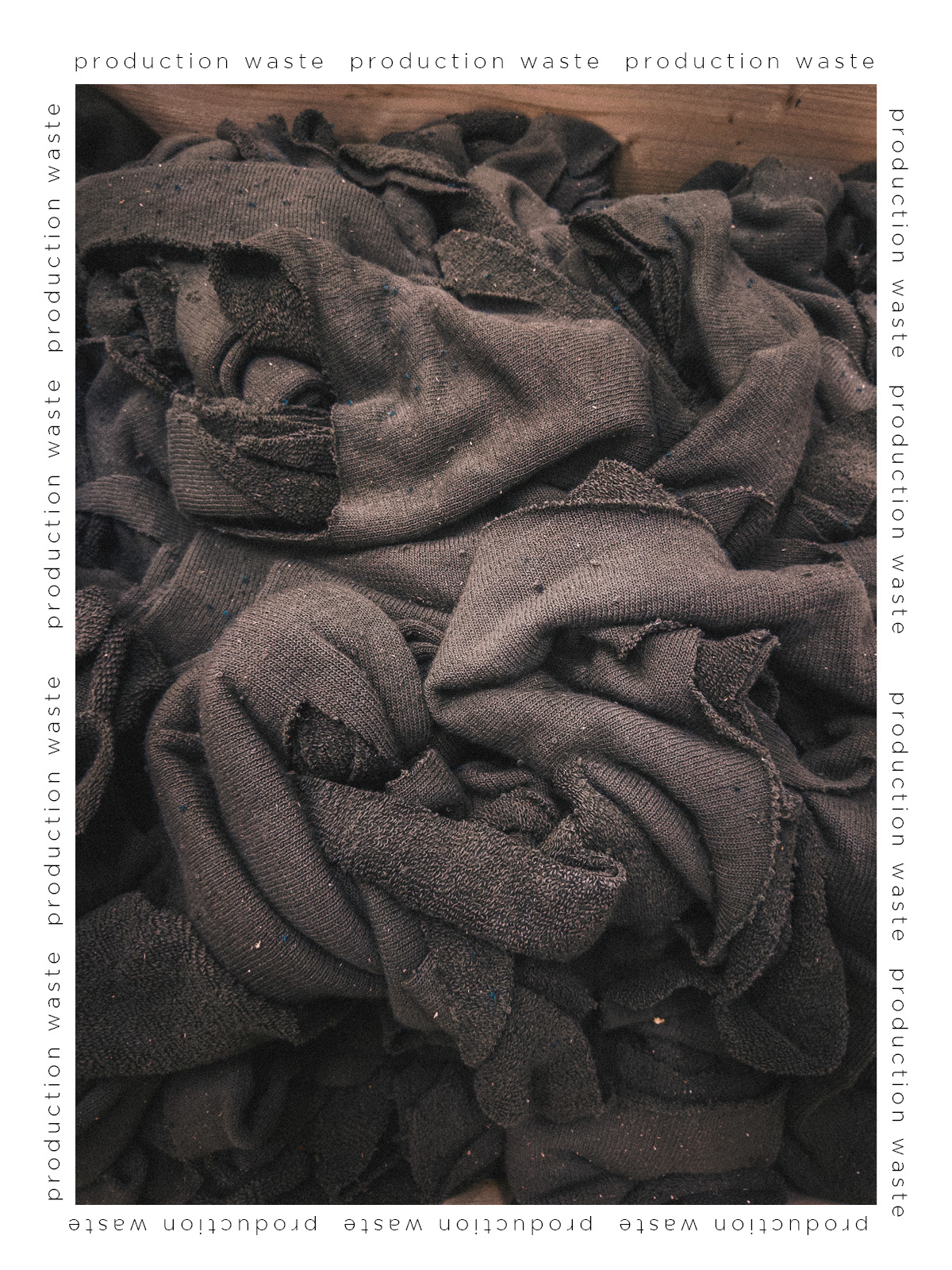

The first step in Woolpower Forward is about making the most of what we already have and taking responsibility for the resources we use. When we cut material for our regular products, small leftover pieces remain. For years, we’ve turned this waste into our felted material, and we’ll continue to do so. But now, we’re taking the next step.

The wool fibers in our production waste are of such high quality that they can be reused. That’s why, over the past few years, we’ve been testing how to spin them into a new yarn. This yarn can be used to create new products, and now we’re ready to test it in real life. As a first step, we’ve produced two sweaters made from our own production waste, in a small, limited batch.

We dream of a system where every garment lasts a long time, and where the material gets a second chance once the garment has reached the end of its life. Until then, we start where we can: by making use of our production waste. Because this is not only about recycled material. By collecting our own waste and spinning it into new yarn which is then knitted, finished, and sewn into new products in our factory, we create a closed loop where the wool fibers are refined and can continue to live on in new forms.

Full Zip Hood Jacket

A unisex hooded jacket with a full-length zipper, knitted in our iconic Ullfrotté Original material. The difference lies in the yarn: this version uses a new quality made of 70% recycled production waste from our factory in Östersund, blended with 30% new fibres. The result is a material that offers the same functionality, durability, and comfort as our other garments, but produced in a more resource-efficient way.

The jacket is entirely knitted and sewn in our factory in Östersund, where the process has been tested and adjusted to ensure the material works in practice. The Full Zip Hood Jacket is a reliable everyday garment that functions both as an outer layer on milder days and as a mid-layer when it gets colder. The hood is shaped to fit closely to the head, providing flexible protection. Available in green or grey.

Half Zip Crewneck

A unisex sweater with a crew neck and half-length zipper. Knitted in Ullfrotté Original – the same unique material used in our regular garments – but here with a newly developed yarn. The yarn consists of 70% recycled production waste from our own manufacturing and 30% new fibres, creating a material with the same warmth and functionality as usual, but with a more efficient use of resources.

The sweater is entirely knitted and sewn in our factory in Östersund. Every step of the production process has been evaluated to ensure quality, durability, and manufacturability. The Half Zip Crewneck is a functional sweater, designed for everyday use and built to meet all daily needs. This style is a beloved favorite making its return after many years. Available in green or grey.

Everything starts with what’s left over

This is how production waste from our own factory is turned into new yarn.

Step 1: Production Waste

The production waste is collected at our preparation department in the Östersund factory and sent to a spinning mill in Italy.

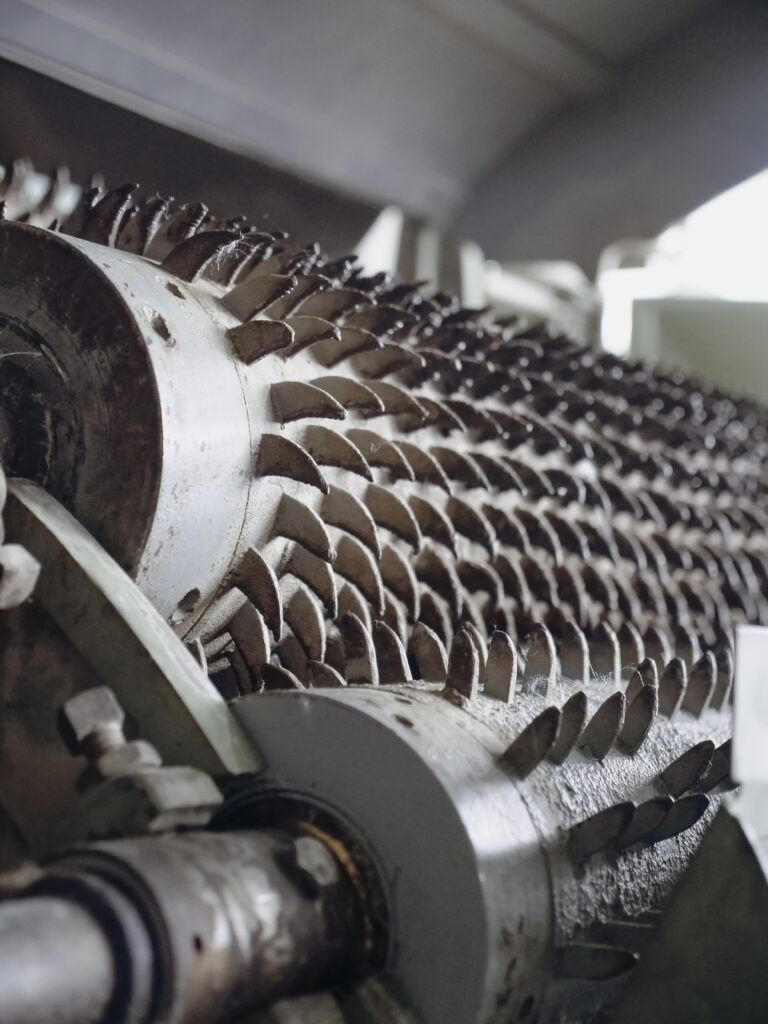

Step 2: Shredding

The production waste is shredded into fibers by a partner in Biella, Italy. The shredded material is then packed into bales and sent to GTI’s factory in Mongrando.

Step 3: Blending and Conditioning

In the Mongrando factory, the recycled fibers are blended with 30% new fibers (virgin wool). The fibers are brushed, lightly oiled, and passed through a resting area to achieve the right moisture content and structure before carding.

Step 4: Carding

The fibers are carded into a thin web in multiple directions to create strength. The fluffy material is formed into slivers, which are rolled onto beams ready for spinning.

Step 5: Spinning and Steaming

The slivers are spun into yarn in two stages:

-

Sliver → bobbins (twist is added)

-

Bobbins → cones (wax is applied and more yarn can be wound)

During spinning, the machine automatically identifies weak points and creates splices where needed. Finally, the yarn is steamed to fix it and stabilize its structure.

Step 6: The Finished Yarn Returns to Woolpower

The new yarn is then knitted, finished, and sewn into new garments at our factory in Östersund.

Our journey toward a new material

Taking responsibility for the entire process is a good thing, but it also means that things take time. Our project to produce garments from recycled yarn has been paused at times when regular production demanded all our resources, and the journey has been filled with both progress and setbacks. Through uncertainty and trial and error, we have slowly found methods to transform production waste into finished garments.

2016-2019

We participated in the pilot project Testbädd för textilåtervinning together with Swerea/RISE. Production waste was shredded and spun into new yarn for testing, but the result was too weak to work in our machines. However, the project demonstrated the potential and laid the foundation for further development.

2020

After the pilot project ended, we took over the work ourselves and tested the yarn that had been produced. The results showed that the fibers became too short during mechanical processing, making the yarn too weak for use in production. It became clear that we needed to build our own value chain to move the project forward toward a functional production process.

2021

The work intensified and new collaborations with spinning mills were established. A set of specifications was developed, and yarns blended with virgin wool were produced, which improved the strength. The first garments were knitted from recycled yarn and met sufficient quality for further testing, while we also established internal routines for handling production waste.

2022

A year marked by reflections on whether the new method could even be implemented alongside our regular production, which continued as usual. We got caught up in questions about workflows, methods, and how the concept would best fit into the product range, which meant that tangible progress was limited. Despite this, the year became an important period of reflection for understanding how the project could actually be realized.

2023

We developed a plan for how existing yarn could be used in a first, smaller production run. The process for collecting and sorting production waste was completed, and new trial batches of yarn were ordered. Internal tests showed good quality, making it possible to start preparing for small-scale production.

2024

Work on recycled yarn progressed slowly, but important insights emerged. During the year, the idea was born to gather development projects in a new platform, Woolpower FORWARD, to test sustainable solutions on a smaller scale before scaling them up. In this way, the recycled yarn project gained a new role as the first step in a larger effort toward the sustainable production of the future.

2025

The year began with a first bulk order of recycled yarn in two colors. Production workflows for knitting, finishing, and sewing were trained, including trial production to streamline handling. During the autumn, final details and adjustments were made in preparation for full production, and the first garments made from recycled yarn were produced on a larger scale.

We move Forward.

But never away from our core: responsible textile production in Östersund.

Just like our other garments, these are entirely produced in our factory in Östersund: from yarn to finished product. The recycled material comes from the waste generated when we produce our Full Zip Jackets and Vest 400. When our partner in Italy spins new yarn from this waste, it is sent back to us to be knitted, cut, and sewn into new products.

Introducing a new material requires careful evaluation. Throughout the project, we have tested knitting machine settings, conducted wash tests, and sewn prototypes to ensure quality at every step.

Now we are ready to release the first garments. Design and functionality meet our standards – and what we are testing next is how smoothly a smaller production series works in practice.

Some of us who have worked on the development of these products are:

Mikael, Knitting

Petra, Sewing

Monika, Development, Sewing

Jacob, Product Development

Ida, Quality

Jenny, Project Lead & Product Development

More projects within Forward

Read more about ongoing and completed projects within Woolpower Forward.

Forward FAQ

Do you have questions about Woolpower Forward? You might find the answer here. If not, feel free to get in touch with us!